More than wheel detection

The foundation of an axle counting system is the wheel sensor. Today’s wheel sensors function under various operating principles, including mechanical, magnetic or inductive. Over the past few decades, inductive wheel sensors have become the gold standard for train detection, primarily due to their high reliability and minimal required maintenance.

Wheel sensors are used to detect the presence of a train, direction of travel, speed and other critical safety information. They are also used to trigger various types of trackside equipment such as AEI card readers or lubricators. Wheel sensors are attached to the rail and detect train wheels that pass over them. This represents the first action in the chain of events that provides important track occupancy status and other vital and non-vital information to the operator.

How does the technology work?

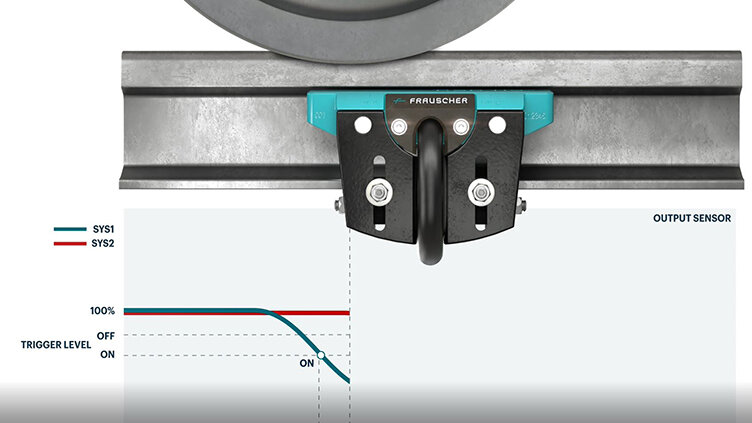

Inductive wheel sensors consist of transmitting and receiving coils. Vital wheel sensors will typically contain two such coil systems, identified below as system 1 and system 2. The coils are protected by a fiberglass reinforced housing, and are completely sealed to provide the highest level of protection against various environmental conditions.

The System 1 and System 2 coils are analog constant current loops. In the video, System 1’s current is illustrated by the blue curve, and System 2’s current by the red curve. When there is no wheel present on top of the sensor, both currents are maintained at a calibrated 100% level. However, when an axle passes over the wheel sensor, it dampens the inductive field, along with the current in the systems.

No trackside electronics

The only required trackside equipment is the wheel sensor, that can be mounted on either rail. Installation simply involves clamping the sensor to the rail, no drilling required. The sensor has an integrated pigtail cable that terminates at a trackside connection box. There are no electronics inside this box, and a signaling cable can then be homerun from the connection box to the wayside enclosure, which can be as far as six miles from the wheel sensor.

Quick and easy mounting of Frauscher wheel sensors

With a wide range of uses and applications, wheel detection systems featuring Frauscher wheel sensors are viewed as the gold standard globally. One important reason is the ease of installation. The Frauscher rail claw makes the process of mounting wheel sensors a quick and easy task.

Using the rail claw, wheel sensors are simply clamped to the rail, without drilling, in approximately five minutes per sensor. Furthermore, they can be used on a wide range of rail profiles. A recommended maintenance cycle of just once in two years minimizes overall life cycle costs.